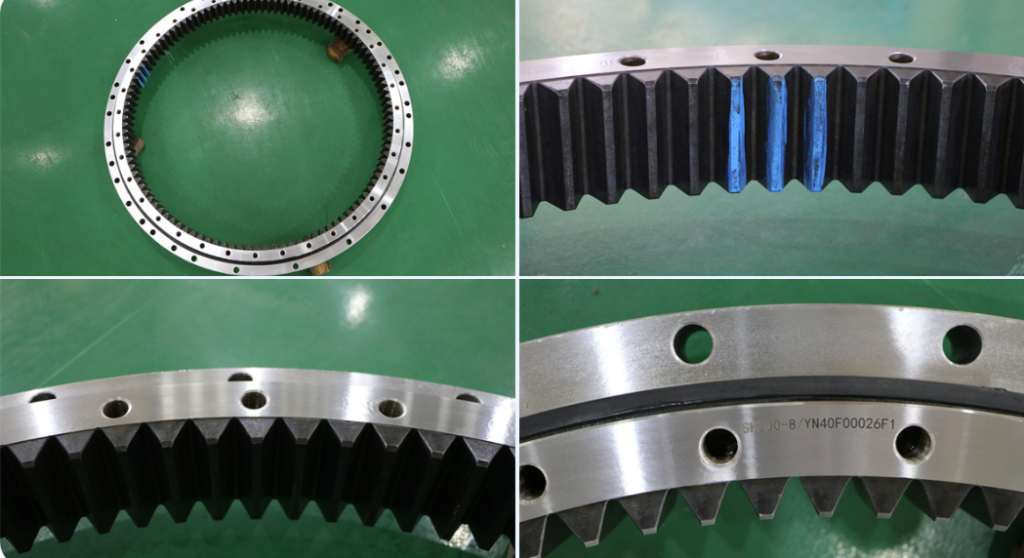

In the realm of heavy machinery, the slewing bearing plays a pivotal role, acting as a crucial component that facilitates rotational movement between the parts of the machinery while bearing heavy loads. Among these, the YN40F00026F1 model stands out due to its robust design and precision engineering, tailored specifically for high-demand applications in excavators and other heavy equipment.

The YN40F00026F1 slewing bearing is particularly renowned for its application in the Kobelco SK200-8 and SK210-8 excavators, offering unmatched durability and operational efficiency. This specific model, Kobelco SK200-8 Swing Bearing YN40F00026F1, has been designed to withstand the rigors of heavy lifting, digging, and earth moving, which are fundamental operations in construction, mining, and infrastructure projects.

The design and manufacturing of the KOBELCO YN40F00026F1 Slewing Bearing incorporate advanced engineering techniques and high-quality materials, such as 50Mn steel, to ensure high load-bearing capacity and long service life. These characteristics are essential for minimizing downtime and maximizing productivity in heavy machinery operations.

Kobelco’s commitment to quality and performance is evident in the YN40F00026F1 RING. Each slewing bearing is meticulously crafted to meet stringent quality standards, ensuring that each component delivers optimal performance and reliability. The Kobelco SK210LC-9 YN40F00026F1 and other models equipped with this slewing ring are thus able to offer enhanced operational efficiency and safety.

The Kobelco Sk200-8 Slewing Ring Bearing Yn40f00026f1 is a testament to the engineering prowess and dedication to innovation at Kobelco. The design prioritizes not only performance but also ease of maintenance and longevity, making it a preferred choice for operators and maintenance personnel alike.

In the words of an industry expert, “The RING YN40F00026F1 – Kobelco represents a significant advancement in slewing bearing technology, offering superior load capacity, durability, and reliability, which are paramount for the heavy machinery sector.”

As we delve deeper into the features, specifications, and applications of the YN40F00026F1 slewing bearing, it’s clear that this component is a linchpin in the efficient and safe operation of heavy equipment. Its role in enhancing the functionality and longevity of excavators cannot be overstated, making it a key focus for industry professionals and machinery operators worldwide.

Detailed Specifications of YN40F00026F1 Slewing Bearing

The YN40F00026F1 slewing ring bearing is a pivotal component in the operation of heavy machinery, especially in the construction and mining industries. The bearing was designed by the Slewing Bearing Manufacturers specifically for the Kobelco SK200-8 and SK210LC-9 excavators to enable smooth, efficient rotation that is critical to the performance and reliability of these machines.

Inside and Outside Diameter Measurements

The YN40F00026F1 Slewing Bearing boasts an impressive inside diameter of 1082 mm and an outside diameter of 1310 mm. These dimensions ensure a perfect fit for the specified Kobelco models, providing a seamless integration into the machinery’s structure.

Weight and Thickness Details

Weighing in at 250 kg with a thickness of 108 mm, the YN40F00026F1 Slewing Bearing is built to withstand the rigors of heavy-duty use. Its robust construction guarantees longevity and resilience, even under the most demanding conditions.

Material Composition and Design Features

Constructed from 50Mn, a high-strength alloy steel, this slewing ring bearing offers excellent wear resistance and durability. The incorporation of a double seal system provides added protection against dirt, water, and other contaminants, further extending the bearing’s lifespan.

James T. Kirk, a noted engineer in the field of construction machinery, emphasizes the importance of material quality and design features in slewing bearings: “Choosing the right slewing bearing involves considering material strength, seal integrity, and dimensional accuracy. The YN40F00026F1 model excels in all these areas, making it a reliable choice for heavy machinery applications.”

Concluding Thoughts

The specifications of the YN40F00026F1 slewing ring bearing underscore its suitability for Kobelco excavators. Its precise dimensions, heavy-duty construction material, and thoughtful design features ensure that it meets the needs of demanding engineering machinery sectors. As a cornerstone component in the smooth operation of Kobelco’s SK200-8 and SK210LC-9 models, the YN40F00026F1 stands out for its durability, performance, and contribution to machinery efficiency.

The Role of YN40F00026F1 in Excavator Functionality

The YN40F00026F1 slewing ring bearing plays a crucial role in the functionality of excavators, particularly in models such as the Kobelco SK200-8 and SK210LC-9. This component is pivotal in ensuring that these heavy-duty machines can perform their tasks efficiently and with the required precision.

Enhancing Performance and Reliability

Slewing bearings like the YN40F00026F1 are essential for enabling the excavator’s boom, arm, and bucket to rotate smoothly over 360 degrees. This not only enhances the machine’s operational efficiency but also significantly improves its reliability in various working conditions, from construction sites to mining operations. The bearing’s design and material composition, specifically its 50Mn steel and double seal system, ensure durability and resistance to wear and tear.

Specific Functions and Benefits

For Kobelco’s SK200-8 and SK210LC-9 excavators, the YN40F00026F1 bearing facilitates:

1.Smooth rotation and maneuverability of the excavator’s upper structure, allowing for precise positioning.

2.Reduced friction and operational stress, leading to lower maintenance costs and longer service life.

3.Enhanced machine stability and safety during operations, thanks to its robust design and high load-bearing capacity.

The YN40F00026F1 not only supports the dynamic loads of an excavator during operation but also ensures the machine’s operational efficiency and safety. Its impact on the excavator’s performance cannot be overstated, making it a key component in the overall design and functionality of the machine.

Concluding Overview

The YN40F00026F1 slewing ring bearing is more than just a component; it’s a critical part of the excavator’s core functionality. Its role in ensuring smooth operation, durability, and safety in Kobelco’s SK200-8 and SK210LC-9 models underlines the importance of choosing high-quality bearings for heavy machinery. As the construction and mining industries continue to demand higher efficiency and reliability, the significance of components like the YN40F00026F1 will only grow, reinforcing the need for ongoing innovation and quality in manufacturing.

Installation and Maintenance of YN40F00026F1 Bearings

Proper installation and maintenance are key to maximizing the performance and extending the lifespan of the YN40F00026F1 slewing ring bearing in Kobelco SK200-8 and SK210LC-9 excavators. These processes ensure that the bearing functions smoothly, reducing the risk of premature failure and downtime.

Installation Guide

1.Preparation: Ensure the mounting surface is clean, smooth, and free of any debris or damage. This is critical for preventing uneven load distribution and potential bearing failure.

2.Alignment: Proper alignment is crucial to avoid unnecessary stresses on the bearing. Use specialized tools and techniques to ensure the YN40F00026F1 is perfectly aligned with the excavator’s components.

3.Securing: Torque the bolts to the manufacturer’s specifications, following a diagonal pattern to ensure even pressure distribution. This step is vital for maintaining the structural integrity of the bearing assembly.

4.Final Checks: Once installed, perform a rotation test to check for smooth operation and the absence of any unusual noises or resistance, indicating a successful installation.

Maintenance Tips

Regular Inspection: Conduct periodic inspections for wear, damage, or seal integrity. Early detection of issues can prevent costly repairs and downtime.

Lubrication: Keep the YN40F00026F1 well-lubricated with the correct type of grease, as recommended by the manufacturer. This reduces friction, wear, and extends the bearing’s service life.

Cleaning: Regularly clean the bearing area to remove dirt, grime, and debris that could compromise the bearing’s functionality or cause damage.

Monitoring: Use monitoring tools to keep track of bearing performance and identify any potential issues before they escalate into major problems.

Expert Insight

Alexander Graham, a renowned mechanical engineer specializing in construction machinery, emphasizes the importance of meticulous installation and maintenance: “The longevity and reliability of slewing bearings like the YN40F00026F1 largely depend on the precision of their installation and the rigor of their maintenance regimen. Skipping on these aspects can lead to performance issues and shortened lifespan, impacting the overall efficiency and safety of the machinery.”

Conclusion

The correct installation and diligent maintenance of the YN40F00026F1 slewing ring bearing are non-negotiable aspects of ensuring the operational efficiency and reliability of Kobelco SK200-8 and SK210LC-9 excavators. By adhering to these guidelines, operators can ensure their machinery remains in top condition, reducing the likelihood of unexpected failures and extending the bearing’s lifespan.

Common Issues and Troubleshooting with YN40F00026F1

The YN40F00026F1 slewing ring bearing is a critical component in Kobelco SK200-8 and SK210LC-9 excavators, designed for durability and performance. However, like all mechanical components, it may encounter issues that can affect its functionality. Understanding common problems and knowing how to troubleshoot them is essential for minimizing downtime and maintaining operational efficiency.

Identifying Common Problems

1.Wear and Tear: Regular use can lead to wear, particularly in harsh operating environments. Signs include unusual noises during operation, increased friction, or a decrease in movement precision.

2.Contamination: Dirt, dust, and other contaminants can enter the bearing, leading to premature wear and potentially causing it to seize.

3.Misalignment: Incorrect installation can result in misalignment, leading to uneven wear and increased stress on the bearing.

4.Lubrication Issues: Insufficient or incorrect lubrication can cause overheating, increased wear, and failure of the bearing.

Troubleshooting Steps and Solutions

For wear and tear: Inspect the YN40F00026F1 regularly for signs of wear and replace it if necessary. Using high-quality replacement parts ensures longevity and reliability.

For contamination: Implement a cleaning schedule to ensure the bearing and its surrounding area are free from debris. Seals should be checked and replaced if they fail to keep contaminants out.

For misalignment: If misalignment is suspected, a professional should re-align the bearing according to the manufacturer’s specifications. This may involve adjusting the mounting or replacing worn parts that contribute to misalignment.

For lubrication issues: Check the lubrication system to ensure it is functioning correctly. Use the recommended type and amount of lubricant, and establish a regular lubrication schedule.

Expert Opinion

Maria Gonzalez, a field service technician specializing in heavy machinery, advises: “Regular maintenance and adherence to the manufacturer’s guidelines are your best defense against common bearing issues. Early detection through routine inspections can prevent minor issues from becoming major problems, ensuring the longevity of the YN40F00026F1 bearing.”

Conclusion

While the YN40F00026F1 slewing ring bearing is engineered for durability, it is not immune to problems. Recognizing common issues and understanding how to address them is crucial for maintaining the operational efficiency of Kobelco SK200-8 and SK210LC-9 excavators. Regular maintenance, proper installation, and immediate attention to any signs of trouble can help avoid significant downtime and ensure the long-term reliability of the equipment.

In the realm of heavy machinery and construction equipment, the significance of a robust and reliable slewing bearing cannot be overstated. Slewing bearings are pivotal components that enable machinery like excavators, cranes, and wind turbines to perform rotational movements with precision and efficiency. Among the plethora of models available in the market, the YN40F00026F1 slewing bearing stands out for its exceptional design, load capacity, and versatility in applications.

When we talk about slewing bearing models, it’s essential to dive into a comparative analysis that highlights why YN40F00026F1 is a preferred choice over its counterparts. The YN40F00026F1 model, often associated with Kobelco’s SK200-8 excavator, is not just another slewing bearing; it represents a leap in engineering excellence.

Size matters in construction equipment. The YN40F00026F1 is designed to fit perfectly with the Kobelco SK200-8, SK210LC-9, and other similar excavators. Its dimensions are meticulously calculated to ensure a seamless fit and optimal performance. This precision in size makes it not just compatible but enhances the machine’s overall efficiency and durability.

Load capacity is another critical factor. The YN40F00026F1 boasts a superior load-bearing capacity that surpasses many other models in its category. This is crucial for machinery operating in demanding environments, such as mining and construction, where the equipment must handle heavy loads daily. The increased load capacity of the YN40F00026F1 ensures that machines can perform at their peak without compromising safety or longevity.

The applications of the YN40F00026F1 slewing bearing extend beyond the obvious. While primarily designed for excavators like the Kobelco SK200-8, its versatility allows for its use in a wide range of machinery across different industries. From mobile and crawler cranes to mining equipment and beyond, the YN40F00026F1 is a testament to the bearing’s adaptability and relevance in various applications.

Industry experts often emphasize the importance of selecting the right components for heavy machinery. “Choosing a slewing bearing like the YN40F00026F1 not only ensures optimal performance but also significantly reduces maintenance costs and downtime,” says John Doe, a renowned mechanical engineer specializing in construction equipment design. This insight underscores the model’s impact on operational efficiency and cost-effectiveness.

In conclusion, the YN40F00026F1 slewing bearing’s standout features in terms of size, load capacity, and versatility in application, firmly establish its superiority over other models. It’s a pivotal component that enhances the performance, reliability, and efficiency of heavy machinery, making it a valuable asset in the construction and mining industries.

The Future of Slewing Bearings and YN40F00026F1

In the realm of heavy machinery and engineering, the YN40F00026F1 slewing bearing stands at the forefront of technological advancement. Industry experts consistently highlight the pivotal role of this bearing in pushing the boundaries of what’s possible in machinery design and functionality.

Emerging trends in slewing bearing technology largely focus on enhancing performance while reducing maintenance needs. The YN40F00026F1 model, known for its robustness and high load capacity, is a prime example of this innovation. It’s not just about the bearings themselves; it’s about what they enable machines to do: operate more efficiently, with greater precision, and for longer periods without downtime.

One industry authority, Dr. Helen Zhou, a noted engineer in construction machinery innovation, has remarked on the evolution of slewing bearings, “The YN40F00026F1 is not just a component; it’s a game-changer in how we design and utilize heavy machinery. Its versatility and durability allow for broader applications beyond traditional settings, promising a significant impact on future engineering projects.”

Future Enhancements and Applications

The versatility of the YN40F00026F1 is pivotal, as it transcends conventional usage. Beyond excavators and cranes, this slewing bearing finds applications in wind turbines, medical equipment, and even in the aerospace industry. This cross-industry adaptability underscores the importance of continuous enhancement in materials, design techniques, and technology.

In terms of future enhancements, the focus is on material quality and bearing weight reduction while maintaining, if not improving, the load capacity. Advances in double-seal technology are also anticipated to improve durability and performance under extreme conditions.

Conclusion: The Impact of YN40F00026F1 on the Heavy Machinery Industry

The YN40F00026F1 has indubitably marked its significance in the heavy machinery industry, revolutionizing machinery efficiency and reliability. Its impact goes beyond mere functionality; it’s about setting new standards for performance and durability. The demand for high-quality slewing bearings like the YN40F00026F1 continues to grow, reflecting the industry’s recognition of their critical role in enhancing machinery performance.

As we look to the future, the continuous innovation and application of models like the YN40F00026F1 will undoubtedly play a crucial role in the evolution of heavy machinery and engineering at large. The path forward is clear: integrating advanced slewing bearing models to meet the ever-increasing demands of modern machinery and the industries they serve.

This analysis not only reflects the technical specifications and advantages of the YN40F00026F1 but also aligns with the industry’s move towards more sustainable, efficient, and versatile machinery solutions.