SKF slewing ring bearings are critical components in various industrial applications, offering exceptional durability, precision, and load-bearing capabilities. As a global leader in bearing technology, SKF has earned a reputation for excellence and innovation in the design and manufacturing of slewing rings.

Slewing rings play a vital role in machinery and equipment that require rotational movement, such as cranes, excavators, wind turbines, and medical imaging devices. These bearings facilitate smooth and precise rotation while supporting heavy loads and withstanding harsh operating conditions.

SKF’s wide range of slewing bearing models meet the needs of different industries and applications, and Slewing Bearing Manufacturers provide customers with reliable solutions that meet their specific requirements. In this article, we will explore the features, benefits, and applications of SKF Slewing Ring Bearings models, highlighting their importance in various sectors.

Overview of SKF Slewing Ring Bearings Models

SKF slewing ring bearings are pivotal components in a wide range of machinery, offering solutions that accommodate axial, radial, and moment loads in a single compact design. These bearings are crucial for the functionality and efficiency of various applications, including heavy machinery in the construction, mining, and excavation sectors, as well as in mobile and crawler cranes. SKF’s range of slewing ring models is designed to meet diverse operational requirements, ensuring reliability, durability, and performance. Here’s an overview of the SKF Slewing Ring Bearings models and their distinguishing features:

Light Series Slewing Rings

These slewing rings are designed for applications where operational efficiency and weight reduction are crucial. They are typically used in light to medium-duty applications, such as in packaging machinery, assembly lines, and light cranes. Despite their lightweight design, they provide exceptional performance and are capable of handling axial, radial, and moment loads effectively.

Standard Series Slewing Rings

SKF’s standard series slewing rings are the workhorse of their lineup, offering a balance between performance and durability. They are suitable for a wide range of applications, from construction machinery to wind turbines, providing reliable service under varying operational conditions. These slewing rings come in various configurations, including single-row four-point contact ball bearings and double-row angular contact ball bearings, to accommodate different load types and sizes.

Heavy Series Slewing Rings

Designed for the most demanding applications, the heavy series slewing rings are capable of supporting substantial loads. These bearings are ideal for use in heavy-duty machinery such as large excavators, mining equipment, and large cranes. They feature robust construction and are engineered to withstand harsh operational environments, ensuring longevity and reliability.

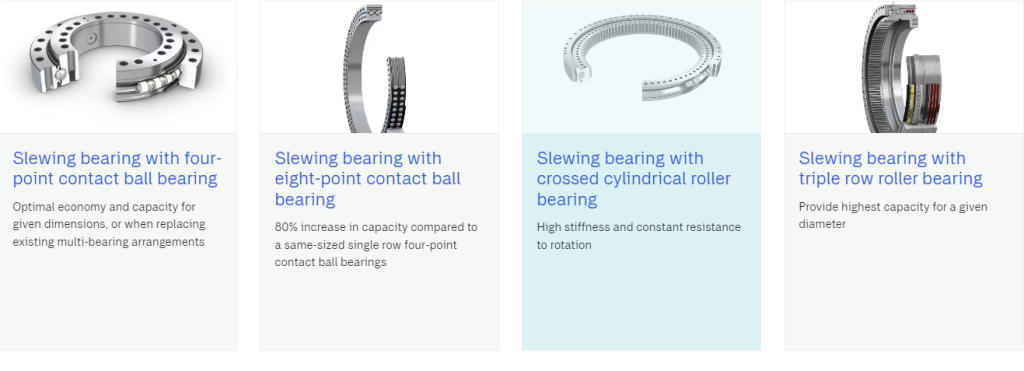

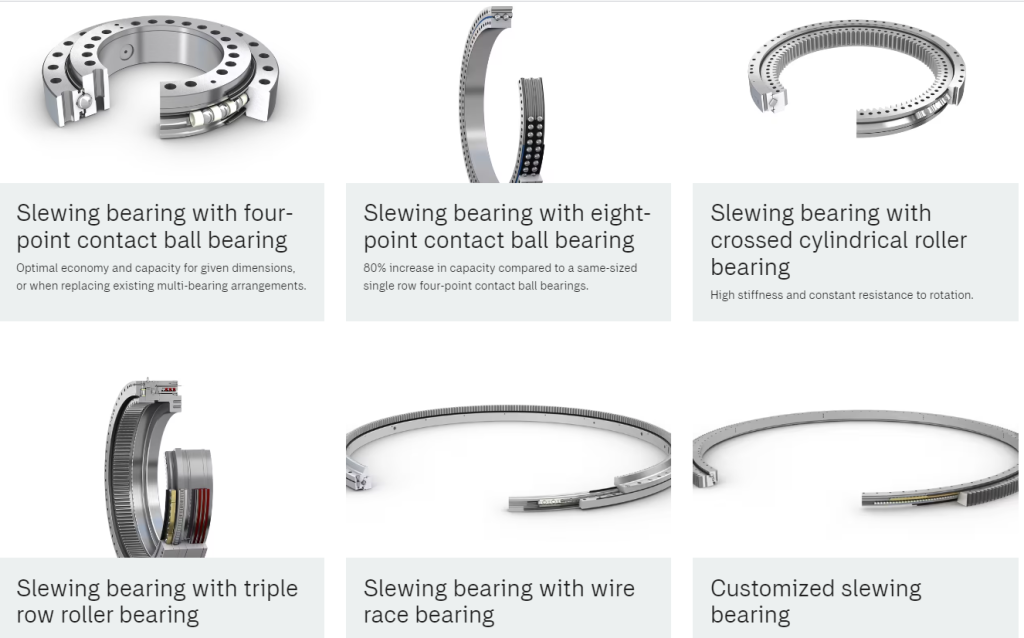

Types of SKF Slewing Rings:

Below is a summary of the main types of SKF Slewing Ring Bearings presented in a table format for clarity and ease of comparison:

| Type | Features | Applications |

| Single-Row Four-Point Contact Ball Slewing Rings | – One row of steel balls.<br>- Four-point contact between balls and raceways.<br>- Supports axial loads, radial loads, and tilting moments. | – Cranes<br>- Excavators<br>- Aerial platforms |

| Double-Row Angular Contact Ball Slewing Rings | – Two rows of steel balls with different diameters.<br>- Parallel arrangement enhances load capacity and stability. | – Heavy-duty cranes<br>- Rotating tables |

| Crossed Roller Slewing Rings | – Rollers arranged in a crossed configuration.<br>- High rotational accuracy and greater capacity to withstand tilting moments. | – Radar and satellite antennae<br>- Machine tools<br>- Robotics |

| Three-Row Roller Slewing Rings | – Three rows of rollers accommodate axial loads, radial loads, and tilting moments separately.<br>- High load capacity. | – Heavy machinery such as tunnel boring machines<br>- Large cranes<br>- Offshore applications |

| Customized Slewing Rings | – Tailored to specific requirements regarding dimensions, materials, and load capacities.<br>- SKF’s engineering capabilities allow for bespoke solutions. | – Applications with unique requirements not met by standard offerings.<br>- Projects requiring specific design considerations. |

This table provides an overview of the different types of SKF Slewing Ring Bearings, highlighting their key features and common applications, showcasing SKF’s ability to cater to a wide range of industrial and mechanical needs with precision and reliability.

SKF Slewing Ring Bearings are engineered to deliver superior performance, reliability, and durability in demanding applications.

Key features include:

High load-carrying capacity: SKF Slewing Ring Bearings are designed to withstand heavy axial, radial, and moment loads, ensuring optimal performance and longevity.

Precision engineering: Built to tight tolerances and subjected to rigorous quality control measures, SKF Slewing Ring Bearings offer exceptional accuracy and repeatability.

Corrosion resistance: SKF utilizes advanced materials and surface treatments to enhance the corrosion resistance of slewing rings, ensuring reliable operation even in harsh environments.

Modular design: Many SKF slewing rings feature a modular design, allowing for easy installation, maintenance, and replacement of components, minimizing downtime and reducing total cost of ownership.

SKF Slewing Ring Models

In the world of engineering machinery, from excavators and construction equipment to mining apparatus and mobile cranes, the SKF slewing ring model plays a pivotal role in operational efficiency and durability. SKF, a leading name in bearing technology, offers a range of slewing ring models designed to meet the varied demands of the heavy machinery industry. This article delves into the intricacies of SKF Slewing Ring Bearings models, highlighting their nomenclature, applications, and key distinguishing features.

The SKF Slewing Ring Bearings model nomenclature is a systematic method for identifying the type, size, and specifications of slewing rings. Each aspect of the model name provides insight into the product’s design and capabilities. For instance, models prefixed with “RKS” denote SKF’s range of slewing bearings, followed by numbers and letters indicating the bearing’s type, diameter, and specific design features. Understanding this nomenclature is essential for selecting the appropriate slewing ring for your machinery, ensuring compatibility and optimal performance.

SKF offers a comprehensive range of slewing ring models to cater to different machinery and operational requirements. These include:

| Model Number | Design Type | Gear Configuration |

| RKS.302070202001 | Four-point contact ball slewing bearing | External gear |

| RKS.312290202001 | Crossed cylindrical roller slewing bearing | Internal gear |

| RKS.312410101001 | Crossed cylindrical roller slewing bearing | Internal gear |

| RKS.312410102001 | Crossed cylindrical roller slewing bearing | Internal gear |

| RKS.313500404001 | Crossed cylindrical roller slewing bearing | Internal gear |

| RKS.314310101001 | Crossed cylindrical roller slewing bearing | Internal gear |

| RKS.322300101001 | Crossed cylindrical roller slewing bearing | External gear |

| RKS.324012324001 | Crossed cylindrical roller slewing bearing | External gear |

| RKS.413290203001 | Crossed cylindrical roller slewing bearing | Internal gear |

| RKS.425060101001 | Crossed cylindrical roller slewing bearing | External gear |

| RKS.425060201001 | Crossed cylindrical roller slewing bearing | External gear |

| RKS.425060621001 | Crossed cylindrical roller slewing bearing | External gear |

| RKS.427020101001 | Crossed cylindrical roller slewing bearing | External gear |

| RKS.427050403001 | Crossed cylindrical roller slewing bearing | External gear |

| RKS.512080101001 | Crossed cylindrical roller slewing bearing | Internal gear |

| RKS.900155101001 | Four-point contact ball slewing bearing | Without gear |

| RKS.901175101001 | Four-point contact ball slewing bearing | Without gear |

| RKS.921150303001 | Crossed cylindrical roller slewing bearing | External gear |

| RKS.921155203001 | Crossed cylindrical roller slewing bearing | Without gear |

| RKS.951145101001 | Four-point contact ball slewing bearing | Without gear |

Each model is engineered to support radial, axial, and moment loads, making them versatile for various engineering machinery, including excavators, construction machinery, mining equipment, and mobile and crawler cranes.

The key features that set SKF slewing ring models apart include their design innovation, material quality, and engineering precision. SKF Slewing Ring Bearings are known for:

SKF slewing ring models are distinguished by several key features that underscore the company’s commitment to design innovation, material quality, and engineering precision. These features ensure that SKF Slewing Ring Bearings meet the highest standards of performance and reliability in various applications. Here are the key characteristics that set SKF slewing rings apart:

Design Innovation

Optimized Geometries: SKF Slewing Ring Bearings feature optimized raceway and rolling element geometries that enhance load distribution and increase bearing life.

Sealing Solutions: Advanced sealing solutions are incorporated to protect against contaminants and extend service life, even in the most challenging environments.

Integrated Features: Some models offer integrated gears, lubrication holes, and mounting holes, facilitating easier installation and maintenance.

Material Quality

High-Quality Steel: SKF uses high-quality, through-hardened bearing steel that offers superior fatigue strength and wear resistance, ensuring durability and long service life.

Surface Treatments: Select models undergo specialized surface treatments for increased resistance to wear and corrosion, catering to applications in harsh environments.

Engineering Precision

Precise Manufacturing: SKF employs state-of-the-art manufacturing technologies to achieve high precision in the production of slewing rings, ensuring tight tolerances and superior fit.

Custom Engineering: SKF offers custom engineering services to meet specific application requirements, including unique loads, speeds, and environmental conditions, providing tailored solutions that perfectly fit the needs of each customer.

Versatility and Range

Wide Product Range: SKF’s extensive product range includes various designs and sizes to cater to a broad spectrum of applications, from light-duty machinery to heavy industrial equipment.

Application-Specific Solutions: The diversity of the product line ensures that there is an SKF slewing ring for virtually any application, including wind turbines, cranes, medical equipment, and marine applications.

Sustainability and Support

Sustainability Efforts: SKF is committed to sustainability, with slewing rings designed for energy efficiency and long life, reducing environmental impact.

Global Support Network: Customers benefit from SKF’s global network of support and expertise, including technical assistance, maintenance services, and training, ensuring optimal performance and reliability of the slewing rings throughout their lifecycle.

The Importance in Engineering Machinery

SKF Slewing Ring Bearings are indispensable in the engineering machinery industry. Their robust design and engineering make them suitable for a wide range of applications, from excavators and construction equipment to mining apparatus and mobile cranes. The selection of the appropriate SKF Slewing Ring Bearings model can significantly impact the efficiency, safety, and lifespan of the machinery.

Choosing the right SKF Slewing Ring Bearings model is crucial for the performance and longevity of engineering machinery. By understanding the nomenclature, available models, and their specific applications, professionals in the excavator industry, construction machinery, mining equipment, and mobile and crawler cranes can make informed decisions that optimize their machinery’s performance. SKF’s commitment to innovation, quality, and engineering excellence ensures that their slewing rings meet the highest standards, providing reliable and efficient solutions for the heavy machinery industry.

SKF slewing rings find applications across a wide range of industries, including but not limited to:

Construction machinery: Cranes, excavators, and concrete pumps rely on SKF slewing rings for smooth and precise rotation under heavy loads.

Mining equipment: Draglines, excavators, and stacker reclaimers utilize SKF slewing rings to withstand the extreme operating conditions encountered in mining operations.

Renewable energy: Wind turbines and solar tracking systems rely on SKF slewing rings to enable efficient energy generation by precisely orienting components to capture maximum sunlight or wind energy.

Aerospace: Aircraft, satellites, and space telescopes use SKF slewing rings for critical functions such as antenna positioning, payload deployment, and satellite tracking.

5. Selecting the Right SKF Slewing Ring for Engineering Machinery:

SKF Slewing Ring Models Explained

In the world of engineering machinery, from excavators and construction equipment to mining apparatus and mobile cranes, the SKF slewing ring model plays a pivotal role in operational efficiency and durability. SKF, a leading name in bearing technology, offers a range of slewing ring models designed to meet the varied demands of the heavy machinery industry. This article delves into the intricacies of SKF slewing ring models, highlighting their nomenclature, applications, and key distinguishing features.

Breakdown of the SKF Slewing Ring Model Nomenclature

The SKF slewing ring model nomenclature is a systematic method for identifying the type, size, and specifications of slewing rings. Each aspect of the model name provides insight into the product’s design and capabilities. For instance, models prefixed with “RKS” denote SKF’s range of slewing bearings, followed by numbers and letters indicating the bearing’s type, diameter, and specific design features. Understanding this nomenclature is essential for selecting the appropriate slewing ring for your machinery, ensuring compatibility and optimal performance.

I can offer examples of possible types of SKF Slewing Ring Bearings and their application scenarios to give a rough understanding.

- Single-Row Four-Point Contact Ball Slewing Bearings (RKS. Series)

Model Example: RKS.121400101001

Features: This type of slewing bearing has a single row of rolling elements with four-point contact capable of supporting axial, radial, and moment loads simultaneously.

Applications: Suitable for applications requiring medium load capacity, such as light cranes, wind turbines, and medical equipment. - Double-Row Different Diameter Ball Slewing Bearings (RKS. Series)

Model Example: RKS.222600101001

Features: Equipped with two rows of balls of different diameters, enhancing the bearing’s load capacity to better withstand complex loads.

Applications: Commonly used in applications requiring high load capacity, like heavy excavators, tower cranes, etc. - Single-Row Crossed Roller Slewing Bearings (RKS. Series)

Model Example: RKS.312410101001

Features: Rollers are arranged in a crossed pattern, offering high rigidity and load capacity, particularly suitable for applications that must support high overturning moments.

Applications: Appropriate for high-precision requirements, such as industrial robots, rotary conveyance equipment, etc. - Customized Slewing Bearings (RKS. Series)

Model Example: RKS.901175101001

Features: SKF provides customization services, designing and manufacturing slewing bearings according to specific application needs, including special sizes, materials, or sealing solutions.

Applications: Suitable for applications where standard models do not meet special requirements, such as specific engineering machinery, marine platforms, etc.

Overview of the Range of Models Available and Their Specific Applications

SKF offers a comprehensive range of slewing ring models to cater to different machinery and operational requirements. These include:

Single-row four-point contact ball slewing bearings: Ideal for applications requiring high precision and medium loads, such as in mobile cranes and excavators.

Double-row angular contact ball slewing bearings: Suitable for heavier loads with a compact design, often used in truck-mounted cranes and stackers.

Crossed cylindrical roller slewing bearings: Designed for applications needing high stiffness and minimal deflection, like tunnel boring machines and large excavators.

Each model is engineered to support radial, axial, and moment loads, making them versatile for various engineering machinery, including excavators, construction machinery, mining equipment, and mobile and crawler cranes.

Key Features That Differentiate SKF Slewing Ring Models

The key features that set SKF slewing ring models apart include their design innovation, material quality, and engineering precision. SKF slewing rings are known for:

High load-carrying capacity: Ensuring durability and reliability under heavy operational loads.

Precision engineering: Offering smooth rotation and control, crucial for machinery precision and safety.

Customizable options: Tailored solutions are available to meet specific operational requirements, enhancing performance and lifespan.

The Importance in Engineering Machinery

SKF Slewing Ring Bearings are indispensable in the engineering machinery industry. Their robust design and engineering make them suitable for a wide range of applications, from excavators and construction equipment to mining apparatus and mobile cranes. The selection of the appropriate SKF Slewing Ring Bearings model can significantly impact the efficiency, safety, and lifespan of the machinery.

Conclusion

Choosing the right SKF Slewing Ring Bearings model is crucial for the performance and longevity of engineering machinery. By understanding the nomenclature, available models, and their specific applications, professionals in the excavator industry, construction machinery, mining equipment, and mobile and crawler cranes can make informed decisions that optimize their machinery’s performance. SKF’s commitment to innovation, quality, and engineering excellence ensures that their slewing rings meet the highest standards, providing reliable and efficient solutions for the heavy machinery industry.

Customization and Engineering Support:

In the realm of engineering machinery, where the precision and durability of components can directly impact operational efficiency and safety, selecting the right bearing solution is paramount. SKF, a leader in bearing technology, understands the critical role that slewing rings play in the heavy machinery industry, including in excavators, construction equipment, mining devices, and mobile as well as crawler cranes. Recognizing the diverse and sometimes unique requirements of these applications, SKF offers customization services for slewing ring bearings, ensuring that every customer can obtain a bearing solution that precisely meets their specific needs.

Tailored Solutions through Collaboration

The journey to a custom slewing ring solution begins with a collaborative effort between the customer and SKF’s team of engineers and application specialists. This partnership is crucial for understanding the specific challenges and performance requirements unique to each customer’s application. Whether it’s a requirement for higher load capacity, improved rotational speed, or resistance to extreme environmental conditions, SKF’s customization services are designed to address these needs head-on.

By engaging directly with customers, SKF taps into its deep well of engineering expertise to design custom slewing ring solutions that not only meet but exceed expectations. This hands-on approach allows for a detailed analysis of the application, considering factors such as operational loads, speeds, and environmental exposures, to tailor a slewing ring that delivers optimal performance.

Comprehensive Engineering Support

SKF’s commitment to customer satisfaction extends beyond the initial design phase. The company provides comprehensive engineering support throughout the design, testing, and implementation phases. This ensures that the custom slewing ring seamlessly integrates into the customer’s machinery, providing the expected performance improvements and reliability enhancements.

The testing phase is particularly critical, as it validates the design’s effectiveness in real-world conditions. SKF employs state-of-the-art testing facilities and methodologies to simulate the operational stresses and strains that the slewing ring will face. This rigorous testing regime guarantees that the final product will not only meet the technical specifications but also withstand the demands of its intended application.

Ensuring Seamless Integration and Optimal Performance

The ultimate goal of SKF’s customization service is to ensure the seamless integration and optimal performance of its slewing ring bearings in customer applications. By offering tailor-made solutions, SKF addresses the very heart of machinery performance issues, enhancing operational efficiency, and extending equipment lifespan. The result is a slewing ring bearing that fits perfectly within the customer’s machinery, contributing to smoother operations, reduced maintenance requirements, and increased overall reliability.

SKF’s customization services for slewing ring bearings embody the company’s commitment to engineering excellence and customer satisfaction. By offering tailored solutions and comprehensive support, SKF ensures that its customers receive slewing ring bearings that are not just fit for purpose but optimized for their specific applications. This dedication to customization and quality underlines SKF’s role as a trusted partner in the heavy machinery industry, capable of addressing the unique challenges and performance requirements of any project.

In essence, SKF empowers customers to enhance the performance and reliability of their machinery with custom slewing ring bearings, supported by unparalleled engineering expertise. This commitment to innovation and customer support ensures that SKF remains at the forefront of bearing technology, delivering solutions that meet the evolving needs of the engineering machinery sector.

In conclusion, SKF slewing ring models represent a cornerstone of precision engineering and reliability, offering unmatched performance and durability across a wide range of industries and applications.

With their advanced design, robust construction, and superior load-carrying capacity, SKF slewing rings are trusted by engineers, manufacturers, and operators worldwide to deliver precise rotational motion and ensure the smooth operation of critical equipment.

Whether it’s lifting heavy loads in construction, extracting minerals in mining, harnessing renewable energy, or exploring the cosmos in aerospace, SKF slewing rings play a vital role in enabling technological advancements and driving innovation across industries.

Understanding the Design and Construction of SKF Slewing Rings

SKF slewing rings are precision-engineered components designed to facilitate smooth and efficient rotational movement in machinery and equipment. These rings play a crucial role in various industries, including construction, mining, renewable energy, aerospace, and more. In this section, we will delve into the intricate design and construction of SKF slewing rings, highlighting their key features and specifications.

- Robust Construction:

SKF slewing rings are constructed using high-quality materials, such as alloy steels, to ensure durability and reliability in demanding applications.

The rings undergo advanced manufacturing processes, including heat treatment and precision machining, to achieve optimal strength, hardness, and dimensional accuracy.

Each slewing ring is meticulously inspected and tested to meet stringent quality standards, ensuring consistent performance and longevity. - Modular Design:

SKF slewing rings feature a modular design that allows for flexibility in configuration and customization to suit specific application requirements.

The modular components include inner and outer rings, rolling elements (such as balls or rollers), seals, lubrication systems, and mounting features.

This modular design enables easy assembly, maintenance, and replacement of individual components, minimizing downtime and reducing overall lifecycle costs. - Raceway Geometry:

SKF slewing rings are engineered with precision-machined raceways on both the inner and outer rings to accommodate the rolling elements.

The raceway geometry is optimized to distribute loads evenly across the bearing surfaces, minimizing stress concentrations and extending the service life of the slewing ring.

Advanced computer-aided design (CAD) and finite element analysis (FEA) techniques are employed to optimize the raceway profile for maximum load-carrying capacity and fatigue resistance. - Sealing and Lubrication:

SKF slewing rings are equipped with effective sealing solutions to prevent contamination ingress and retain lubricants within the bearing assembly.

Various sealing options, including labyrinth seals, lip seals, and advanced sealing materials, are available to suit different environmental conditions and operating environments.

Additionally, SKF offers integrated lubrication systems, such as centralized grease lubrication and automatic lubrication systems, to ensure optimal performance and extend maintenance intervals. - Mounting and Installation:

SKF provides comprehensive support for the mounting and installation of slewing rings, including detailed technical documentation, mounting instructions, and on-site assistance if required.

Specialized tools and equipment are available to facilitate proper alignment, torqueing, and fastening of slewing ring components during installation.

Proper mounting practices are essential to ensure optimal performance, reliability, and safety of the slewing ring assembly in operation.

In summary, SKF slewing rings are meticulously designed and constructed to deliver superior performance, reliability, and durability in a wide range of industrial applications. By incorporating advanced materials, precision engineering, and innovative technologies, SKF continues to set the standard for excellence in slewing ring design and manufacturing.

Real-world Applications of SKF Slewing Ring Models

SKF slewing ring models find diverse applications across various industries, thanks to their robust construction, precision engineering, and reliable performance. In this section, we explore some real-world applications where SKF slewing rings play a critical role:

- Construction Machinery:

SKF slewing ring models are extensively used in construction machinery such as excavators, cranes, and concrete pumps.

In excavators, slewing rings enable smooth rotation of the excavator arm, facilitating efficient digging, lifting, and material handling operations.

Cranes rely on slewing rings for precise rotation of the boom and jib, allowing for accurate positioning of heavy loads during lifting and construction activities.

Concrete pumps utilize slewing rings to support the rotating boom assembly, enabling precise placement of concrete in construction projects. - Wind Turbines:

SKF slewing ring models are integral components of wind turbine systems, where they facilitate yaw and pitch control mechanisms.

Yaw bearings enable the wind turbine nacelle to rotate horizontally, allowing the turbine blades to align with the wind direction for optimal energy capture.

Pitch bearings adjust the angle of the turbine blades to optimize their aerodynamic performance and maximize energy generation efficiency.

SKF slewing rings ensure smooth and reliable operation of wind turbines, even in harsh environmental conditions, contributing to the advancement of renewable energy production. - Mining Equipment:

Mining equipment such as excavators, stackers, and reclaimers rely on SKF slewing rings for efficient material handling and processing operations.

In large excavators, slewing rings support the rotating upper structure, enabling the excavator bucket to dig, load, and transport bulk materials with precision and stability.

Stackers and reclaimers use slewing rings to pivot the conveyor boom, facilitating the stacking and reclaiming of bulk materials in mining and bulk material handling facilities.

- Aerospace and Defense:

SKF slewing ring models are utilized in aerospace and defense applications, including aircraft landing gear systems, radar antennas, and missile launchers.

In aircraft landing gear systems, slewing rings support the weight of the aircraft during landing and provide smooth rotation for retracting and extending the landing gear assemblies.

Radar antennas mounted on ships, aircraft, and ground-based installations rely on slewing rings for precise azimuth and elevation adjustments to track targets accurately.

Missile launchers utilize slewing rings to pivot and elevate the launch platform, enabling rapid deployment and targeting of missiles in defense operations. - Industrial Machinery:

SKF slewing ring models find numerous applications in industrial machinery such as packaging machines, rotating platforms, and indexing tables.

Packaging machines use slewing rings to facilitate the smooth and precise movement of conveyor belts, robotic arms, and other components involved in the packaging process.

Rotating platforms and indexing tables utilize slewing rings to enable rotational movement for assembly, welding, inspection, and testing operations in manufacturing facilities.

In summary, SKF slewing ring models play a vital role in a wide range of real-world applications, spanning industries such as construction, renewable energy, mining, aerospace, defense, and manufacturing. Their reliability, durability, and precision make them indispensable components in machinery and equipment designed for diverse operational requirements and challenging environments.

Advantages and Benefits of SKF Slewing Rings

When it comes to selecting slewing rings for critical applications, SKF stands out as a top choice for engineers and manufacturers worldwide. Let’s delve into the compelling advantages and benefits of choosing SKF slewing rings over competing products:

- Superior Performance and Precision Engineering:

SKF slewing rings are meticulously engineered to deliver unparalleled precision and performance in demanding applications.

The advanced design and manufacturing processes ensure tight tolerances, smooth operation, and precise motion control, even under heavy loads and harsh operating conditions.

By choosing SKF slewing rings, engineers can rely on consistent performance and optimal efficiency, enhancing the overall reliability and productivity of their machinery and equipment. - Exceptional Reliability and Longevity:

SKF slewing rings are renowned for their exceptional reliability and longevity, making them the preferred choice for long-term, mission-critical applications.

Through rigorous testing and quality assurance protocols, SKF ensures that each slewing ring meets stringent performance standards and exceeds customer expectations for durability and service life.

Customers benefit from reduced downtime, maintenance costs, and equipment failures, resulting in increased operational efficiency and profitability over the lifespan of their machinery. - Comprehensive Range of Solutions:

SKF offers a comprehensive range of slewing ring solutions tailored to meet the diverse needs of various industries and applications.

From standard designs to custom-engineered solutions, SKF provides slewing rings in a variety of sizes, configurations, and load capacities to accommodate specific requirements and operating conditions.

This versatility enables engineers to select the optimal slewing ring model for their application, ensuring optimal performance, compatibility, and integration with existing systems. - Testimonials and Endorsements from Industry Experts:

Industry experts and customers worldwide have endorsed SKF slewing rings for their exceptional quality, performance, and reliability.

Testimonials from satisfied customers attest to the superior performance, longevity, and cost-effectiveness of SKF slewing rings in a wide range of applications, including construction, mining, renewable energy, aerospace, and manufacturing.

Prominent industry professionals have recognized SKF as a trusted partner and supplier of high-quality slewing ring solutions, further cementing its reputation as a leader in the field.

In conclusion, SKF slewing rings offer a compelling combination of precision engineering, superior performance, exceptional reliability, and comprehensive solutions, making them the preferred choice for critical applications across industries. By choosing SKF, engineers and manufacturers can optimize the performance, longevity, and efficiency of their machinery and equipment, ensuring maximum uptime, productivity, and profitability.

Future Trends and Innovations in SKF Slewing Ring Technology

In the rapidly evolving landscape of industrial machinery and equipment, SKF is at the forefront of pioneering advancements in slewing ring technology. Let’s explore the exciting future trends and innovations shaping the industry:

Exploration of Emerging Technologies: As industries continue to push the boundaries of performance and efficiency, SKF is actively exploring emerging technologies to enhance slewing ring design and manufacturing processes. From advanced materials to innovative production techniques, SKF is leveraging cutting-edge technologies to develop slewing rings that offer unmatched performance, durability, and reliability.

Advancements in Slewing Ring Design and Manufacturing: SKF is continuously investing in research and development to push the boundaries of slewing ring design and manufacturing. Through state-of-the-art design software, precision engineering, and advanced manufacturing capabilities, SKF is revolutionizing the way slewing rings are conceived, designed, and produced. By optimizing load distribution, reducing friction, and enhancing sealing mechanisms, SKF is able to deliver slewing rings that outperform traditional designs in terms of performance and longevity.

Predictions for Future Developments: Looking ahead, SKF foresees several key developments shaping the future of slewing ring technology.

These include:

1.Integration of IoT and Smart Monitoring: SKF is exploring the integration of IoT (Internet of Things) technology and smart monitoring systems into slewing rings, enabling real-time performance monitoring, predictive maintenance, and remote diagnostics.

2.Lightweight and High-Strength Materials: SKF is researching lightweight and high-strength materials, such as advanced composites and alloys, to reduce weight, improve efficiency, and increase load-carrying capacity in slewing ring applications.

3.Enhanced Sealing and Lubrication Systems: SKF is developing advanced sealing and lubrication systems to improve reliability, prevent contamination, and extend maintenance intervals in harsh operating environments.

4.3D Printing and Additive Manufacturing: SKF is exploring the potential of 3D printing and additive manufacturing techniques to produce complex geometries, custom designs, and prototypes with unparalleled precision and efficiency.

SKF’s Commitment to Innovation: As a global leader in bearing and rotating technology, SKF remains committed to innovation and continuous improvement. By staying ahead of the curve and anticipating the evolving needs of the market, SKF is poised to deliver groundbreaking solutions that redefine the performance and reliability of slewing rings across industries.

In conclusion, SKF is leading the way in driving innovation and shaping the future of slewing ring technology. Through a combination of emerging technologies, advancements in design and manufacturing, and a commitment to innovation, SKF is well-positioned to meet the challenges and opportunities of tomorrow’s industrial landscape.

1.SKF Official Website: Visit SKF’s official website (https://www.skf.com/) to explore their product documentation, technical specifications, and industry insights related to slewing ring technology.

2.Industry Publications: Look for reputable industry publications and journals that cover topics related to bearings, rotating machinery, and industrial technology. Some examples include Engineering360 (https://www.globalspec.com/engineering360), Machinery Lubrication (https://www.machinerylubrication.com/), and Plant Engineering (https://www.plantengineering.com/).

3.Engineering Forums and Communities: Explore online forums and communities where engineers and industry professionals discuss topics related to mechanical engineering and industrial applications. Websites like Eng-Tips Forums (https://www.eng-tips.com/) and Mechanical Engineering Stack Exchange (https://engineering.stackexchange.com/) could provide valuable insights and discussions.

4.Academic Databases: Search academic databases such as IEEE Xplore (https://ieeexplore.ieee.org/), ScienceDirect (https://www.sciencedirect.com/), and Google Scholar (https://scholar.google.com/) for research papers, conference proceedings, and scholarly articles related to slewing ring technology and SKF innovations.

5.SKF Official Website: This is the primary source for detailed product information, technical data, and support resources regarding SKF slewing bearings. https://www.skf.com/us/products/slewing-bearings

6.SKF Official Website: This is the primary source for detailed product information, technical data, and support resources regarding SKF slewing bearings.

SKF Slewing Bearings

7.SKF Product Catalogues: SKF provides extensive product catalogues which can be a valuable resource for finding detailed specifications and information on various SKF slewing ring models. https://www.skf.com/us/industries/metals/products-solutions/skf-slewing-bearings

SKF Bearing Catalogue

8.Technical Articles and Application Examples: SKF often publishes technical articles, case studies, and application examples that can provide insights into the performance, selection, and customization of slewing bearings for specific applications.

SKF Knowledge Centre: SKF Technical Articles https://cdn.skfmediahub.skf.com/api/public/0901d196809590fe/pdf_preview_medium/0901d196809590fe_pdf_preview_medium.pdf